The Department of Mechanical Engineering announced another educational incentive for graduate students as they announced a new graduate certificate in 3-D engineering and additive manufacturing. The new program will launch this fall and is open to graduate students and professionals who are already in the field and are looking to expand their knowledge in the field.

When one hears about UTEP’s academia, most pinpoint its success to the engineering department. However, not many would know what achievements or accomplishments the department has achieved in recent years.

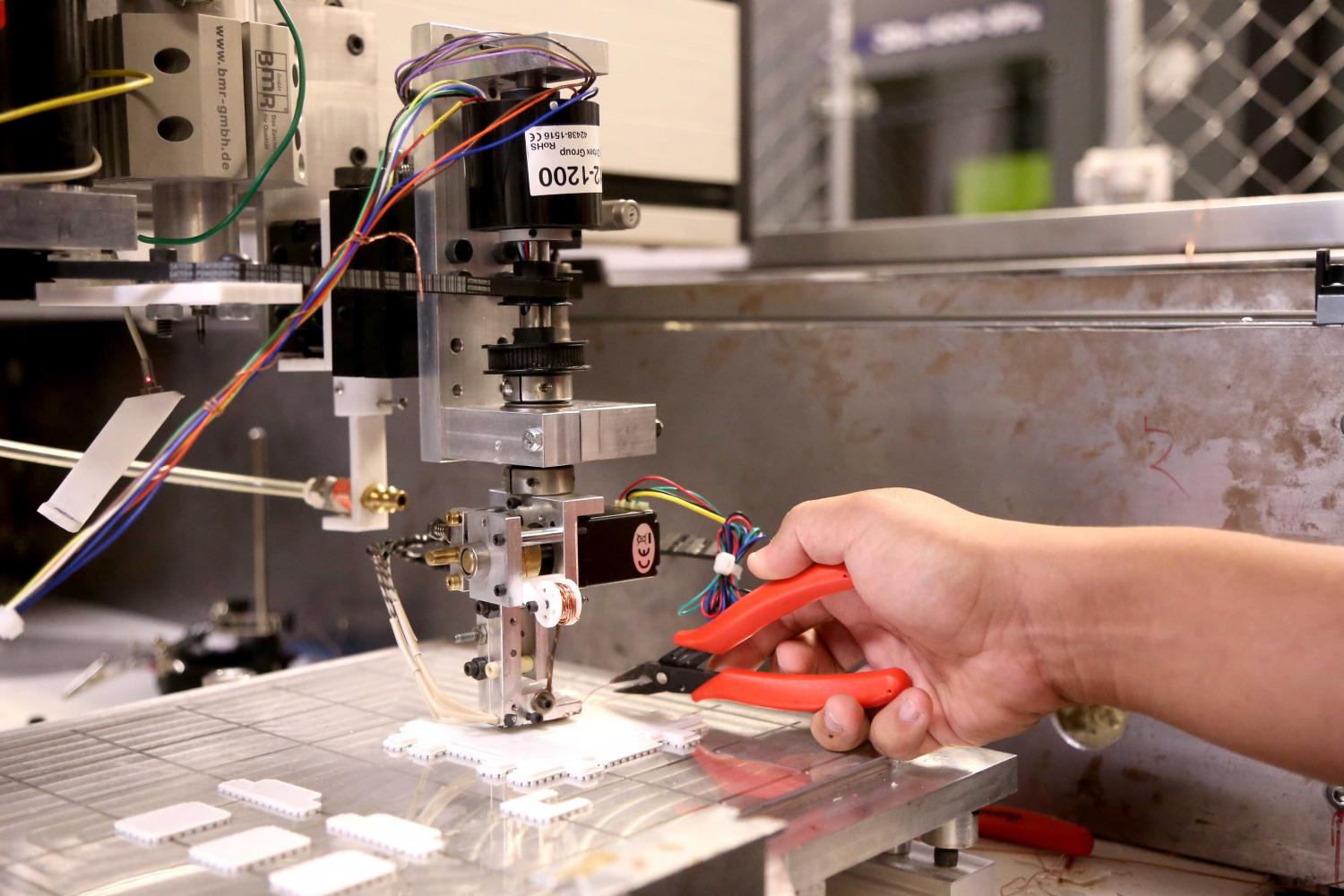

From the W.M. Keck Center, the school’s center for 3-D printing innovation, to housing about 50 3-D printers, to adding new educational programs, such as this certificate for additive manufacturing, the department has revolutionized its programs.

“While a lot of places have 3-D printing capabilities, there are very few in the world that match that expertise and Keck has all the 3-D printing systems you can imagine—all the major printing systems from plastic lithography, to film and melting, to metal and melting,” said Jack Chessa, associate professor of mechanical engineering and graduate program director. “I think it’s outstanding. From a university program standpoint, we have an entity here that really is an authority on this stuff.”

Additive manufacturing and 3-D printing have become recently popular, but for UTEP’s mechanical engineering department, this is not a new subject of study.

In fact, the department has been working in the additive manufacturing field since 2001 and continues to push new boundaries in education.

Mireya Perez, the research administrator in the department, believes that this new certificate will be an added incentive to any engineer hoping to enhance their resume.

“We find that a lot of these working professionals lack some of the newer skills and knowledge they would need in operating 3-D parts,” Perez said. “That’s what we’re trying to do in this program—not only educate the students who are graduating in this program, but also some of these engineers, who are already out in the field, and want to learn about this new technology. More and more companies and industries are picking it up.”

In order to obtain the certificate, an individual must complete a 12-month period of 15 graduate credit hours. The program offers three online lecture courses and two design studio classes, which give students a hands-on experience with the Keck Center’s vast majority of instruments.

The course will be broken down into three sections—an introductory portion, the design aspect and an advanced course, which as Perez describes, will lead new research methods and findings in 3-D printing work.

“Students will be able to actually come into the lab and have the opportunity to work with and be exposed with some of the industry-grade equipment that we have in this facility,” Perez said. “What we think the Keck Center has to offer is the fact that we have such a wide array of technology available here. Anybody coming in here will have exposure to the various technologies, the various machines, the various material types.”

Cesar Terrazas, a research assistant professor in the department, has already been teaching some of these additive manufacturing courses throughout the past year and has received positive feedback from students.

“It’s impacted the students positively because they’ve been able to apply to many different jobs,” Terrazas said. “There’s a boom in this industry. With these classes, they have the opportunity to defend their knowledge in some of these jobs, but with this certificate, it’s going to make it even better and boost opportunities.”

According to Perez, students who have been through the engineering program and taught these additive manufacturing skills have landed jobs at big companies, such as Lockheed Martin, Texas Instruments, Intel, Autodesk and different other mechanical engineering spots.

She said graduates are not only going into the aerospace engineering field, but also the biomedical field, and software companies are also hiring these UTEP students.

“We see that companies are hiring more and more of our students because of their 3-D printing expertise,” Perez said. “They graduate with the knowledge of how to do 3-D printing, but without a degree or certification. So in creating this certificate, we want to actually give them something feasible to show that they have this knowledge in 3-D printing.”

In 2015, UTEP was named the first satellite center for America Makes, which is the National Additive Manufacturing Innovation Institute funded by the Obama administration.

Now, two years later, the program continues to evolve. With this new certificate in place, the school now offers 23 graduate degrees and certifications and eight undergraduate degrees.

Chessa believes that the rapid growth in the department is also closely related to the increase in popularity of 3-D printing.

“I think 3-D printing is one of the first few game-changing engineering applications that you can see that has visibility outside the engineering communities,” Chessa said. “If you look all over the place on social media or websites, this thing of maker communities, 3-D printing is everywhere. Without a doubt, it will have a major impact on engineering development for the next decade at least, if not more. It will be an revolutionary quantum jump.”

Reflecting on the accomplishments that the Keck Center has done, Perez is proud to say that the department is well regarded, not only at the university level, but also nation wide.

She explained that the center receives many different visitors from around the world who wish to check out the different equipment the center has.

“If you go to any 3-D printing conference and say you’re from UTEP, they’ll know where you’re from and know the Keck Center,” Perez said. “We’ve been doing research for so long and we’re trying to expand our educational reach. This would be one way to do it with this educational certification. We’ve been training students for a long time, so now we just want them to strengthen their resume and get a better place in the workspace.”

For more information on the graduate certificate, visit the Keck Center’s website at www.keck.utep.edu.